系统仿真学报 ›› 2022, Vol. 34 ›› Issue (09): 1976-1987.doi: 10.16182/j.issn1004731x.joss.21-0395

收稿日期:2021-05-06

修回日期:2021-06-25

出版日期:2022-09-18

发布日期:2022-09-23

第一作者简介:张洪亮(1979-),男,博士,副教授,研究方向为生产调度优化、精益生产与管理。E-mail:hlzhang@ahut.edu.cn。

基金资助:

Hongliang Zhang( ), Renman Ding, Gongjie Xu

), Renman Ding, Gongjie Xu

Received:2021-05-06

Revised:2021-06-25

Online:2022-09-18

Published:2022-09-23

摘要:

在综合考虑经济指标和环境因素基础上,研究了工件加工时间不确定的多目标柔性作业车间节能调度问题。将工件不确定加工时间描述为区间数,并以最小化最大区间完工时间、区间总能耗为目标构建区间柔性作业车间调度节能问题优化模型。同时,依据区间可能度的支配关系,设计了一种有效求解该问题的区间多目标进化算法。通过15组测试问题,分别对区间多目标进化算法、SPEA-II及NSGA-II进行仿真实验,并采用反转世代距离(inverse generation distance, IGD)和覆盖集测度(C测度)两种性能指标验证了所提算法的可行性和有效性。

中图分类号:

张洪亮,丁仁曼,徐公杰 . 考虑区间工时的多目标柔性作业车间节能调度[J]. 系统仿真学报, 2022, 34(09): 1976-1987.

Hongliang Zhang,Renman Ding,Gongjie Xu . Energy-Efficient Scheduling of Multi-objective Flexible Job Shop Considering Interval Processing Time[J]. Journal of System Simulation, 2022, 34(09): 1976-1987.

表2

符号定义

| 符号 | 定义 |

|---|---|

| n | 待加工工件总数 |

| m | 机器总数 |

| J | 工件集 |

| M | 机器集 |

| ni | 工件Ji 的工序总数 |

| i | 工件序号,i=1,2,···,n |

| j | 工序序号,j=1,2,···,ni |

| k | 机器序号,k=1,2,···,m |

| Oij | 工件Ji 的第j道工序 |

| 工序Oij 在机器Mk 上区间加工时间 |

| 工件Ji 第j道工序在机器Mk 上区间开工时间 |

| 工件Ji 第j道工序在机器Mk 上区间完工时间 |

| 工件Ji 的区间完工时间 |

| L | 一个足够大的正数 |

| pek | 机器Mk 单位时间加工能耗 |

| iek | 机器Mk 单位时间空闲能耗 |

| ce | 车间单位时间公共能耗 |

| 车间区间总加工能耗 |

| 车间区间总空闲能耗 |

| 车间区间公共能耗 |

| 车间区间总能耗 |

| 决策变量: | |

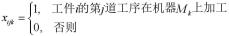

| |

| |

| i=1,2,…,n,s=1,2,…,n,j1,2,…,ni, | |

| t=1,2,…,ns,k=1,2,…,m | |

表6

三种算法对各测试问题求得的IGD测度均值

| 问题 | n×m | IMOEA | NSGA-II | SPEA-II |

|---|---|---|---|---|

| MK01 | 10×6 | 19.226 7 | 95.513 3 | 54.045 2 |

| MK02 | 10×6 | 0 | 227.153 7 | 129.155 7 |

| MK03 | 15×8 | 31.004 7 | 505.801 7 | 545.750 1 |

| MK04 | 15×8 | 5.571 7 | 412.085 7 | 732.203 9 |

| MK05 | 15×4 | 49.952 3 | 250.967 8 | 475.395 8 |

| MK06 | 10×15 | 88.721 2 | 199.328 8 | 882.548 1 |

| MK07 | 20×5 | 301.061 8 | 303.925 1 | 277.056 5 |

| MK08 | 20×10 | 0 | 226.160 1 | 129.112 7 |

| MK09 | 20×10 | 31.942 6 | 150.122 1 | 143.580 7 |

| MK10 | 20×15 | 458.250 5 | 1 773.317 6 | 2269.466 9 |

| MK11 | 30×5 | 183.270 5 | 424.821 5 | 693.501 3 |

| MK12 | 30×10 | 323.719 6 | 591.958 6 | 1231.970 2 |

| MK13 | 30×10 | 181.746 3 | 316.728 5 | 852.865 0 |

| MK14 | 30×15 | 128.647 8 | 405.071 6 | 707.740 3 |

| MK15 | 30×15 | 31.942 6 | 537.898 9 | 1098.573 6 |

表7

三种算法对各测试问题求得的C测度均值

| 问题 | n×m | C(IMOEA, NSGA-II) | C(NSGA-II, IMOEA) | C(IMOEA, SPEA-II) | C(SPEA-II, IMOEA) |

|---|---|---|---|---|---|

| MK01 | 10×6 | 1.000 0 | 0 | 1.000 0 | 0 |

| MK02 | 10×6 | 1.000 0 | 0 | 1.000 0 | 0 |

| MK03 | 15×8 | 1.000 0 | 0 | 1.000 0 | 0 |

| MK04 | 15×8 | 1.000 0 | 0 | 1.000 0 | 0 |

| MK05 | 15×4 | 1.000 0 | 0 | 1.000 0 | 0 |

| MK06 | 10×15 | 0.910 0 | 0.131 7 | 1.000 0 | 0 |

| MK07 | 20×5 | 1.000 0 | 0 | 0.900 0 | 0.360 0 |

| MK08 | 20×10 | 1.000 0 | 0 | 0.825 0 | 0.200 0 |

| MK09 | 20×10 | 1.000 0 | 0 | 1.000 0 | 0 |

| MK10 | 20×15 | 0.970 0 | 0.230 0 | 0.880 0 | 0.240 0 |

| MK11 | 30×5 | 1.000 0 | 0 | 1.000 0 | 0 |

| MK12 | 30×10 | 1.000 0 | 0 | 1.000 0 | 0 |

| MK13 | 30×10 | 0.720 0 | 0.260 0 | 0.300 0 | 0.500 0 |

| MK14 | 30×15 | 1.000 0 | 0 | 1.000 0 | 0 |

| MK15 | 30×15 | 1.000 0 | 0 | 1.000 0 | 0 |

| [1] | 费凡. 面向节能优化的多目标柔性作业车间生产调度方法研究[D]. 合肥: 合肥工业大学, 2018. |

| Fei Fan. Research on Multi-objective Flexible Job Shop Scheduling Method for Energy-saving Optimization[D].Hefei: Hefei University of Technology, 2018. | |

| [2] | 罗雄, 钱谦, 伏云发. 遗传算法解柔性作业车间调度问题应用综述[J]. 计算机工程与应用, 2019, 55(23): 15-21,34. |

| Luo Xiong, Qian Qian, Fu Yunfa. Review of Application of Genetic Algorithms for Solving Flexible Job Shop Scheduling Problems[J]. Computer Engineering and Applications, 2019, 55(23): 15-21,34. | |

| [3] | Piroozfard H, Wong K Y, Wong W P. Minimizing Total Carbon Footprint and Total Late Work Criterion in Flexible Job Shop Scheduling by Using an Improved Multi-objective Genetic Algorithm[J]. Resources, Conservation and Recycling (S0921-3449), 2018, 128: 267-283. |

| [4] | Wu X, Shen X, Li C. The Flexible Job-shop Scheduling Problem Considering Deterioration Effect and Energy Consumption Simultaneously[J]. Computers & Industrial Engineering (S0360-8352), 2019, 135: 1004-1024. |

| [5] | Caldeira R H, Gnanavelbabu A, Vaidyanathan T. An Effective Backtracking Search Algorithm for Multi-objective Flexible Job Shop Scheduling Considering New Job Arrivals and Energy Consumption[J]. Computers & Industrial Engineering (S0360-8352), 2020, 149: 106863. |

| [6] | 朱光宇, 徐文婕. 考虑能耗与质量的机床构件生产线多目标柔性作业车间调度方法[J]. 控制与决策, 2019, 34(2): 252-260. |

| Zhu Guangyu, Xu Wenjie. Multi-objective Flexible Job Shop Scheduling Method for Machine Tool Component Production Line Considering Energy Consumption and Quality[J]. Control and Decision, 2019, 34(2): 252-260. | |

| [7] | 刘彩洁, 徐志涛, 张钦, 等. 分时电价下基于NSGA-Ⅱ的柔性作业车间绿色调度[J]. 中国机械工程, 2020, 31(5): 576-585. |

| Liu Caijie, Xu Zhitao, Zhang Qin, et al. Green Scheduling of Flexible Job Shop Based on NSGA-II under TOU Power Price[J]. China Mechanical Engineering, 2020, 31(5): 576-585. | |

| [8] | 李益兵, 黄炜星, 吴锐. 基于改进人工蜂群算法的多目标绿色柔性作业车间调度研究[J]. 中国机械工程, 2020, 31(11): 1344-1350,1385. |

| Li Yibing, Huang Weixing, Wu Rui. Research on Multi-objective Green Flexible Job Shop Scheduling Based on Improved ABC Algorithm[J]. China Mechanical Engineering, 2020, 31(11): 1344-1350,1385. | |

| [9] | Lin J, Zhu L, Wang Z-J. A Hybrid Multi-verse Optimization for the Fuzzy Flexible Job-shop Scheduling Problem[J]. Computers & Industrial Engineering (S0360-8352), 2019, 127: 1089-1100. |

| [10] | 李俊萱, 王艳, 纪志成. 基于混合QPSO的模糊柔性作业车间调度问题研究[J]. 系统仿真学报, 2020, 32(10): 2010-2021. |

| Li Junxuan, Wang Yan, Ji Zhicheng. Research on Fuzzy Flexible Job Shop Scheduling Problem Based on Hybrid QPSO[J]. Journal of System Simulation, 2020, 32(10): 2010-2021. | |

| [11] | 郑小操, 龚文引. 改进人工蜂群算法求解模糊柔性作业车间调度问题[J]. 控制理论与应用, 2020, 37(6): 1284-1292. |

| Zheng Xiaocao, Gong Wenyin. An Improved Artificial Bee Colony Algorithm for Fuzzy Flexible Job-shop Scheduling Problem[J]. Control Theory & Applications, 2020, 37(6): 1284-1292. | |

| [12] | 杨子豪. 基于强化学习的批处理机随机调度问题研究[D]. 合肥: 合肥工业大学, 2020. |

| Yang Zihao. Research on Stochastic Batch Machine Scheduling Problem Based on Reinforcement Learning[D]. Hefei: Hefei University of Technology, 2020. | |

| [13] | Gu J, Gu M, Lu X, et al. Asymptotically Optimal Policy for Stochastic Job Shop Scheduling Problem to Minimize Makespan[J]. Journal of Combinatorial Optimization, 2018, 36(1): 142-161. |

| [14] | Xiao S, Wu Z, Yu S. A Two-stage Assignment Strategy for the Robust Scheduling of Dual-resource Constrained Stochastic Job Shop Scheduling Problems[J].IFAC-PapersOnLine, 2019, 52(13): 421-426. |

| [15] | Ghasemi A, Ashoori A, Heavey C. Evolutionary Learning Based Simulation Optimization for Stochastic Job Shop Scheduling Problems[J]. Applied Soft Computing (S1568-4946), 2021, 106: 107309. |

| [16] | 李雅琼, 李强, 阳小兰. 考虑非确定加工时间的柔性作业车间调度问题研究[J]. 计算机应用研究, 2018, 35(10): 3016-3019. |

| Li Yaqiong, Li Qiang, Yang Xiaolan. Research on Flexible Job-Shop Scheduling Problem Considering Uncertain Processing Time[J]. Application Research of Computers, 2018, 35(10): 3016-3019. | |

| [17] | 王凌, 郑洁, 王晶晶. 求解区间数分布式流水线调度的混合离散果蝇优化算法[J]. 控制与决策, 2020, 35(4): 930-936. |

| Wang Ling, Zheng Jie, Wang Jingjing. A Hybrid Discrete Fruit Fly Optimization Algorithm for Distributed Permutation Flowshop Scheduling with Interval Data[J].Control and Decision, 2020, 35(4): 930-936. | |

| [18] | 朱艳艳, 徐震浩, 顾幸生. 工序加工时间不确定的可重入调度问题的求解[J]. 控制与决策, 2021, 36(5): 1127-1136. |

| Zhu Yanyan, Xu Zhenhao, Gu Xingsheng. Solution of Reentrant Scheduling Problem with Uncertain Processing Time[J]. Control and Decision, 2021, 36(5): 1127-1136. | |

| [19] | Zhou R, Lei D, Zhou X. Multi-objective Energy-efficient Interval Scheduling in Hybrid Flow Shop using Imperialist Competitive Algorithm[J]. IEEE Access (S2169-3536), 2019, 7: 85029-85041. |

| [20] | Sengupta A, Pal T K. On Comparing Interval Numbers[J].European Journal of Operational Research (S0377-2217), 2000, 127(1): 28-43. |

| [21] | 肖峻, 张跃, 付川. 基于可能度的区间数排序方法比较[J]. 天津大学学报, 2011, 44(8): 705-711. |

| Xiao Jun, Zhang Yue, Fu Chuan. Comparison between Methods of Interval Number Ranking Based on Possibility[J]. Journal of Tianjin University, 2011, 44(8): 705-711. | |

| [22] | 张国辉, 高亮, 李培根, 等. 改进遗传算法求解柔性作业车间调度问题[J]. 机械工程学报, 2009, 45(7): 145-151. |

| Zhang Guohui, Gao Liang, Li Peigen, et al. Improved Genetic Algorithm for the Flexible Job-shop Scheduling Problem[J]. Journal of Mechanical Engineering, 2009, 45(7): 145-151. | |

| [23] | Gong D W, Qin N N, Sun X Y. Evolutionary Algorithms for Multi-objective Optimization Problems with Interval Parameters[C]// 2010 IEEE Fifth International Conference on Bio-Inspired Computing: Theories and Applications (BIC-TA). Changsha, China: IEEE, 2010: 411-420. |

| [24] | 张守京, 王彦亭. 基于改进NSGA2的柔性车间多目标智能调度问题研究[J]. 现代制造工程, 2020(9): 23-31. |

| Zhang Shoujing, Wang Yanting. Research on Multi-objective Intelligent Scheduling of Flexible Job Shop Based on Improved NSGA2[J]. Modern Manufacturing Engineering, 2020(9): 23-31. | |

| [25] | Deb K, Pratap A, Agarwal S, et al. A Fast and Elitist Multiobjective Genetic Algorithm: NSGA-II[J]. IEEE Transactions on Evolutionary Computation (S1089-778X), 2002, 6(2): 182-197. |

| [26] | Brandimarte P. Routing and Scheduling in a Flexible Job Shop by Tabu Search[J]. Annals of Operations Research (S0254-5330), 1993, 41(3): 157-183. |

| [27] | Tian Y, Cheng R, Zhang X, et al. PlatEMO: A MATLAB Platform for Evolutionary Multi-objective Optimization [educational forum][J]. IEEE Computational Intelligence Magazine (S1556-603X), 2017, 12(4): 73-87. |

| [28] | Zitzler E, Thiele L. Multiobjective Evolutionary Algorithms: a Comparative Case Study and the Strength Pareto Approach[J]. IEEE Transactions on Evolutionary Computation (S1089-778X), 1999, 3(4): 257-271. |

| [1] | 陈娟, 郑旺, 刘倩倩, 鲁斌. 基于动态储位分配策略的自动化立库多目标优化[J]. 系统仿真学报, 2025, 37(6): 1435-1448. |

| [2] | 顾文斌, 卿洁瑕, 方杰, 刘斯麒. 改进混合优化算法求解多目标IPPS问题[J]. 系统仿真学报, 2025, 37(5): 1197-1209. |

| [3] | 吴自松, 苌道方, 盖宇春. 基于两阶段混合算法的四向穿梭式密集仓储系统货位分配优化[J]. 系统仿真学报, 2025, 37(5): 1234-1245. |

| [4] | 李敏, 张森, 曾祥光, 王刚, 张童伟, 谢地杰, 任文哲, 张滔. 基于深度强化学习的四足机器人单腿越障轨迹规划[J]. 系统仿真学报, 2025, 37(4): 895-909. |

| [5] | 江雨燕, 马宁, 李艳, 甘如美江, 王付宇. 考虑动态预维护与绿色调度的协同优化问题[J]. 系统仿真学报, 2025, 37(2): 362-378. |

| [6] | 刘翔, 金乾坤. 基于PAC-Bayes的多目标强化学习A2C算法研究[J]. 系统仿真学报, 2025, 37(12): 3212-3223. |

| [7] | 王宁, 毛剑琳, 李大焱, 房程远, 钱诚泽. HCA*框架下的低能耗多机器人路径规划算法[J]. 系统仿真学报, 2025, 37(10): 2630-2642. |

| [8] | 丁新桓, 王华庆, 党旭. 考虑尾气排放的交叉口信号配时多目标优化研究[J]. 系统仿真学报, 2025, 37(10): 2687-2700. |

| [9] | 王科, 官思佳, 殷希彦, 李西兴, 唐红涛. 基于混合遗传禁忌搜索算法的混流装配线平衡优化研究[J]. 系统仿真学报, 2025, 37(1): 167-182. |

| [10] | 李飞行, 邢立宁, 周宇. 基于多目标演化优化的SVM对抗仿真测试算法[J]. 系统仿真学报, 2024, 36(9): 2016-2031. |

| [11] | 李二超, 张生辉. 基于DMOEA-APTC算法的无人机在线航迹规划[J]. 系统仿真学报, 2024, 36(9): 2086-2099. |

| [12] | 张闻强, 王晓萌, 张晓晓, 张国辉. 集配一体化车辆路径规划的混合进化多目标优化[J]. 系统仿真学报, 2024, 36(8): 1914-1928. |

| [13] | 刘卫亮, 闫倩文, 张启亮, 刘帅, 刘长良, 康佳垚, 王昕. 基于虚拟电厂区间主从博弈的车网互动优化调度[J]. 系统仿真学报, 2024, 36(7): 1559-1572. |

| [14] | 蒋权, 魏静萱. 用于动态柔性作业车间调度的实时调度方法[J]. 系统仿真学报, 2024, 36(7): 1609-1620. |

| [15] | 邓明君, 胡辛瑕, 李响, 徐丽萍. 基于车速引导和感应控制的干线协调优化方法[J]. 系统仿真学报, 2024, 36(6): 1309-1321. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||